Monday February 12th, 2024 @ 7 pm to 9 pm EST (Toronto Canada Time Zone)

Module 1: Understanding the fundamentals of commercial refrigeration. Topics include servicing secondary systems, cascade systems and parallel rack system.

Monday February 19th, 2024 @ 7 pm to 9 pm EST (Toronto Canada Time Zone)

Module 2: Why understanding oil management is key to your success. Learning the theory and fundamentals of high side components and taking the mystery out of heat reclaim and head pressure controls.

Monday February 26th, 2024 @ 7 pm to 9 pm EST (Toronto Canada Time Zone)

Module 3: We will review different low side components and how to effectively become more confident at troubleshooting and finding the root problem when you have issues with TEV, EEV, CDS, EPR's and more.

Monday March 4th, 2024 @ 7 pm to 9 pm EST (Toronto Canada Time Zone)

Module 4: All about service and troubleshooting. Learn about service and maintenance procedures that will help you be more confident with your day to day service calls. Deep dive on the sequence of operations of the different systems and get a handle on how to troubleshoot parallel rack issues.

If you have any issues please email support@refrigerationmentor.com

4-week Supermarket Program

w/ Refrigeration Mentor

© 2023 Refrigeration Mentor. All Rights Reserved.

Do you want to have the confidence of a Highly Skilled Refrigeration Professional?

About Refrigeration Mentor

Refrigeration Mentor is a international training and development organization that is dedicated to training, educating, and mentoring refrigeration professionals throughout the industry. The founder, Trevor Matthews who is a Certified Training & Development Professional and a subject matter expert in commercial refrigeration systems, has worked as a technician installing, commissioning, and servicing supermarket racks, commercial refrigeration, and HVAC systems.

Trevor has trained thousands of technicians, managers, and business owners and has helped educators, contractors and manufacturers develop trainings around specific refrigeration topics that met their needs. Trevor takes a systematic approach when designing a program and makes sure the information is easily digestible from servicing and troubleshooting systems to making technologies like CO 2 refrigeration seem simple to work with, while motivating and building confidence in the learners.

We pride ourselves on providing honest, value-adding, and high-quality training services. We work with our clients to customize learning and development programs that meet their specific needs, from technical training design to full program rollouts that focus on building a culture around training, education and mentoring within your organization.

Note: For best results and viewing purpose please use a desktop computer, laptop computer or tablet that has or uses a mic and camera so you get the full feel of the program.

**This course is a continued professional development program to add to your current knowledge & skills and it is not a substitute for your local Refrigeration and HVAC qualifications. Always follow local codes and safety protocols.

Overview

This Supermarket learning program was designed for refrigeration professionals (technicians) who have field experience and don't want to be stressing on jobsites anymore. This is a continuing education program to grow your knowledge on installations, servicing and troubleshooting different supermarket refrigeration systems. The program will improve your knowledge, competency and confidence when working on parallel racks, secondary systems, cascade systems as well as medium and low temperature condensing units.

Do you want to look like a Rockstar in front of your customers, coworkers or boss? Any technician who completes this in depth learning program will have the tools and resources to figure out what system issues they are looking at and resolve them fast and effectively.

I created this learning program from the years of supermarket and commercial field experience and knowledge pass down to me from subject matter experts. If you are looking to become the top technician at your company this course will help you get there.

4-week Supermarket Learning Program

Learning modules will consist of 3 major activities with measurable goals to keep you on track:

1. Each week a 2 hour online instructor led training with interactive work, polls, and quizzes

2. Assignments with on-the-job practical learning

3. Knowledge assessments and Q&As to solidify previous modules

Every module will finish with a knowledge assessment and an assignment.

*This leaning program is not is a controls course. We may bring up some different facility controllers examples in conversation and we may discuss things to look for when trying to solve a problem.

Module 3: Low Pressure Components

Module 2: High Pressure Components

Module 4: Service and Troubleshooting

Module 1: Commercial System Designs

Certification

To earn a certificate of completion of the 4-week Supermarket learning program, the refrigeration professional must finish their quizzes, assignments, and the final knowledge assessment. Following completion of the virtual program, they will receive a certificate from Refrigeration Mentor.

*Virtual Training Schedule:

The following are examples of program content but not limited to.

Module 1: Refrigeration Fundamentals & System Designs

Section 1: Basic Refrigeration and Fundamentals

• How refrigeration works

• Basic components of a refrigeration system

• Compressor, condenser, metering device and evaporator overview

• Review on pressure enthalpy diagram

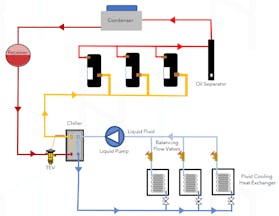

Section 2: Secondary Systems

• Introduction & overview

• Equipment and components

• Review how secondary pump systems work and understand their functionality

Section 3: Cascade Systems

• Introduction & overview

• Equipment and components

• Review how cascade systems work and understand their functionality

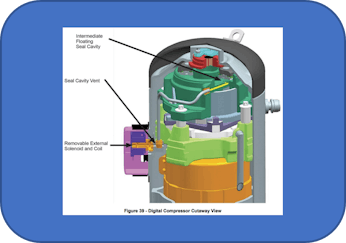

Section 4: Parallel Rack System

• Introduction & overview

• Equipment and components

• Review how parallel systems work and understand their functionality

Section 5: CO2 Booster Systems

• Review CO2 booster system piping and instrumentation diagram (P&ID)

Module 2: High Pressure Side Components

Section 1: High Pressure Safety Switches

• Overview

• Different designs and types

• How to Install them, set each one up, and troubleshooting

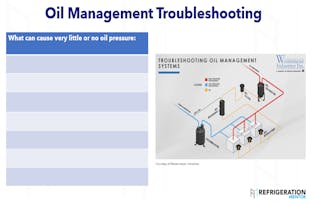

Section 2: Understanding Oil Management

• Understanding the different oil system designs

• Oil separator

• Oil receiver

• Oil filter

• Oil level controls

• Oil solenoids

• How the oil system is controlled

• Discuss how to properly install, service and troubleshoot these components

• How to properly add oil to the system

Section 3: Pressure Reliefs

• Standard pressure settings

• Where they are in the system

• How to install, inspect and replace

Section 4: Condensers

• How they are designed and function

• Learn about the different head pressure controls used

• Types of motors they use

• Setting up a condenser

• Troubleshooting condenser

Section 5: Heat Reclaim

• What does heat reclaim do?

• Types of heat reclaim systems

• How heat reclaim systems are designed and function

• Performance and efficiency

• Function of 3-way heat reclaim valves and how they work

• How to control and setup a heat reclaim system

• Servicing & troubleshooting heat reclaim systems

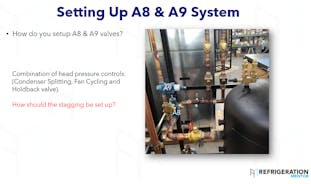

Section 6: Head Pressure Controls

• What is the purpose of using head-pressure controls?

• What are the different head pressure control options?

• How they are designed and function

• Review of A8, A9, OROA, ORI-6, ORD, LAC-4-DS

• Why setting up and controlling is very important.

• Servicing & troubleshooting

Module 3: Low Side System Components

Section 1: Thermal Expansion Valves (TEV’s)

• The basics TEVs

• Understanding the different designs and functions

• Installing, servicing, and troubleshooting TEV’s

Section 2: Electronic Expansion Valves (EEVs)

• What you need to know about electronic expansion valves?

• The basics EEVs

• Understanding the different designs and functions of EEVs

Section 3: Evaporators - Cases & Coils

• Overview

• Components inside case or coils

• Installation service and troubleshooting

Section 4: Evaporator Pressure Regulating Valves (EPR’s)

• Overview

• Different designs and types

• Mechanical

• Electronic

• Installation, service, and troubleshooting

Sections 5: Accumulators

• The purpose of an accumulator

• How they work and where you will find them in the system

• Troubleshooting accumulators

Section 6: Low-Pressure Safety Switches

• Overview

• Different designs and types

• How to install them, set each one up, and troubleshooting

Section 7: Subcoolers

• What is the purpose of Subcooler?

• Types of subcooling systems

• How Subcoolers are designed and function

• Performance and efficiency

• How to control and setup a Subcooler

• Servicing & troubleshooting Subcoolers

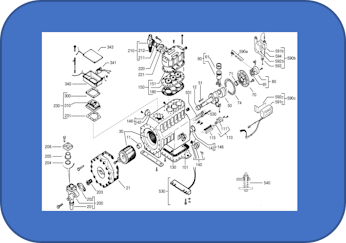

Module 4: Service, Maintenance & Troubleshooting

Section 1: Defrosting Cases & Coils

• Types of defrost (Hot gas, Kool gas, Electric, Off time)

• How each defrost type works

• Setting up defrost schedule

• Troubleshooting frozen coils and defrost systems

Section 2: Service Procedures

• Understanding how to pump down a rack

• Steps and procedures to complete a pump down and things to watch out for

• How to properly pump out a case or coil for field repair and start up

• How to replace a valve, compressor, components, oil controls and motors

Section 3: Sequence of Operation

• Compressor Staging

• Oil Management

• Heat Recovery

• Head Pressure Controls

• Subcooler

• Defrost Cycles

• System and Circuit Pump down

Section 4: System Maintenance Procedures

• Why system maintenance is so important

• How to take an oil sample

• How to check and test the oil separator coalescent filter element, oil line filter driers, liquid line filter drier cores and suction line filters

• How to test and calibrate temperature probes and pressure transducers

• How to test and check the operation of the safety devices such as pressure switches, bleed solenoid valves, and pressure relief valves

• How to properly clean condenser fins, water spay systems, water pads, evaporators coils, case honeycombs and other components

Section 5: System Troubleshooting

• Pressure control trips

• Temperature too high or low

• Compressor issues

• Oil issues

• Condenser issues

• Evaporator fan or case issues

• Defrosting issues

• Heat recovery issues

• Head pressure controls troubleshooting

• Subcooler issues

• Defrosting issues

• Air flow issues